HOT LINE: +86-510-80628100

HOT LINE: +86-510-80628100 HOT LINE: +86-510-80628100

HOT LINE: +86-510-80628100

Stainless steel forged round steel refers to a stainless steel circular bar processed through forging technology, which combines the corrosion resistance and mechanical properties of stainless steel.

Core advantages

1. More compact organization with fewer defects

2. Better mechanical properties

3. Strong controllability of size and accuracy

4. Preserve the corrosion resistance essence of stainless steel

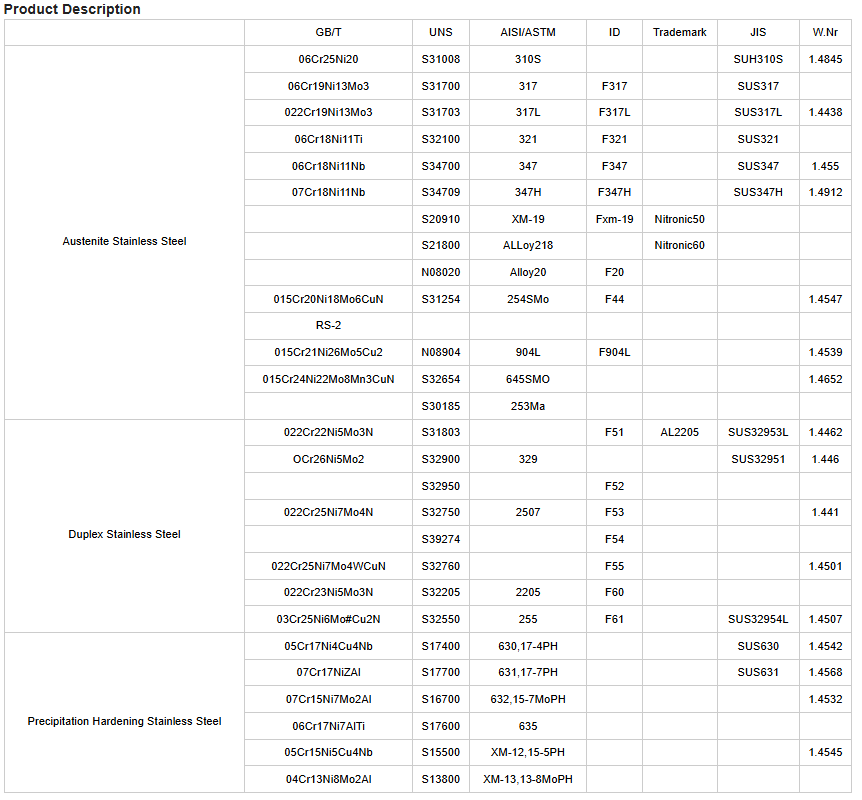

Main classification (by stainless steel material): austenitic stainless steel, martensitic stainless steel, ferritic stainless steel, duplex stainless steel, precipitation hardening stainless steel

Application areas:

1. In the field of mechanical manufacturing, it is used to manufacture high-strength and wear-resistant key parts, such as gears, shafts (motor shafts, machine tool spindles), bolts, nuts, couplings, etc.

2. In the field of petrochemicals, it is used to manufacture equipment components that are resistant to acid, alkali, and high pressure, such as valve cores, pump shafts, flanges, pipeline joints, etc. (commonly made of 316L and duplex steel).

3. Aerospace field: used for manufacturing aircraft engine components, landing gear connectors, etc. (commonly used precipitation hardening steel 17-4PH, duplex steel 2205).

4. Medical device field: used for manufacturing surgical instruments and implantable parts (such as artificial joint shafts), requiring corrosion resistance and biocompatibility (commonly 316L, 440C).

In the field of hydropower/nuclear power, it is used to manufacture turbine shafts, pressure vessel flanges for nuclear power plants, etc., requiring high strength and radiation resistance (commonly used duplex steel, martensitic stainless steel).

Steel grades of austenitic stainless steel, duplex stainless steel, and precipitation hardening stainless steel